- Home Page

- Company Profile

-

Our Products

- Drum Seeder

- Cono Weeder

- Barbed Connector & Fittings

- Spray Irrigation Kit

- Sprinkler Hose

- Drip Irrigation System

- Rain Pipe

- Drip Irrigation Grommet

- Rain Hose & Fittings

- Irrigation Tube

- Spray Pipe

- Lateral Pipe

- Flat Drip Irrigation PIPE

- Lay Flat Hose Pipe

- Drip Tape & Fittings / 16 mm

- Drip Tape & Fittings / 20 mm

- Round Inline Pipe / 16 mm

- ROUND PLAIN / 16 mm

- Home Garden Kit

- FLAT INLINE DRIP KIT

- Drip Irrigation Filter

- Drip System Accessories

- Ball Valves & PVC Fittings

- Venturi Injector

- Drip Lateral Tube & Pipe

- Drip Hole Punch

- End Barbed Cap

- Sprinkler Rain Gun

- Drip Joiner

- FAQs & Testimonials

- Contact Us

Search Products

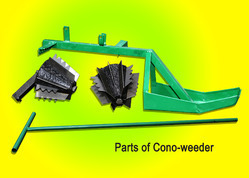

Rotary Cono Weeder

2400.0 INR/Piece

Product Details:

- Usage & Applications Paddy field weeding, Aeration

- Features Lightweight, Rust Resistant, Easy Operation, High Efficiency

- Tool Type Cono Weeder

- Noise Level Zero (Manual Operation)

- Product Type Rotary Cono Weeder

- General Use Weeding and aeration between paddy rows

- Type Manual Push Type

- Click to View more

X

Rotary Cono Weeder Price And Quantity

- 1800.00 - 2400.00 INR/Piece

- 1 Piece

- 2400.0 INR/Piece

Rotary Cono Weeder Product Specifications

- Manual Push Type

- Cono Weeder

- Lightweight, Rust Resistant, Easy Operation, High Efficiency

- Zero (Manual Operation)

- Approx. 240 mm

- Upto 2 Rows

- Manual Push

- Green, Silver

- Direct

- Rotary Cono Weeder

- Depends on Operator

- Human Powered

- None

- Mild Steel, Plastic

- Weeding and aeration between paddy rows

- Approx. 1000 mm x 350 mm x 300 mm

- Paddy field weeding, Aeration

- Efficient weed removal

- Manual

Rotary Cono Weeder Trade Information

- 10 Piece Per Day

- 5-7 Days

Product Description

Weeding is the act of removing unwanted plants from the regular crop in order to increase its profitability. In crop production, weed management is critical since weed removal is costly and difficult later on. The presence of weeds in a field deprives the soil of nutrients and attracts harmful insects, which results in lower yields.

Weed control has been improved over the past two decades through the use of non-chemical management techniques and eco-friendly alternatives to herbicides. The most economically effective way to control weeds is mechanical weeding. The best method of weeding is using a rotary weeder. The wetland weeder that is pulled or pushed by hands has become extremely popular amongst farmers. It can be easily used under shallow water conditions to uproot weeds and bury them in mud.

During a season, farmers should remove weed at least three times. Weeders should be used as soon as weeds germinate as getting weeds out at an early stage is easier.

Instructions to use:

- Weeding is a must at the beginning of the season. Start weeding 20 days after seeding.

- Delayed weeding will cause damage to paddy crop.

- Use a backward and forward motion between rows.

- Continue weeding 15 days later and if possible, a third time as well.

- It is not important to weed the third time, but weeding each time aerates the soil and makes it more fertile.

- It is still beneficial to weed the field a fourth time before the onset of flowering even if the field is already free of weeds.

Critical Points:

Within 20 days of sowing, the first weeding should be conducted.

There should be more water in the field when weeding.

Precision and Efficiency

With adjustable depth control up to 60 mm and compatibility for paddy rows spaced between 200 mm and 250 mm, this cono weeder delivers precise weed removal and effective aeration. Its dual conical drums and 240 mm working width allow for efficient coverage of up to two rows in one pass, maximizing field productivity.

Designed for Paddy Fields

Built for wetland paddy conditions, the weeders corrosion-resistant materials and lightweight structure make it both durable and easy to maneuver. The tool operates quietly, thanks to human-powered direct transmission, and ensures operator safety with protected moving parts, making it well-suited for extended use in challenging environments.

FAQs of Rotary Cono Weeder:

Q: How do I use the Rotary Cono Weeder in my paddy field?

A: Simply position the weeder between the paddy rows (200 mm to 250 mm apart), adjust the depth up to 60 mm as needed, and push manually to operate. The conical drums efficiently uproot weeds and aerate the soil during each forward pass.Q: What are the main benefits of using this weeder in wetland paddy fields?

A: The key benefits include efficient weed control, soil aeration, operator safety due to covered parts, rust resistance, and low maintenance. It improves crop health and yields without the need for fuel or electricity, making it cost-effective and eco-friendly.Q: When should I use the Rotary Cono Weeder during the crop cycle?

A: Operate the weeder during the early stages of paddy growth, specifically after seedlings are firmly established but before weeds become too dense. Regular use throughout the growing season optimizes aeration and weed management.Q: Where is this tool best suited for application?

A: This manual cono weeder is ideal for wetland paddy fields with row spacing between 200 mm and 250 mm, especially where mechanized or chemical weeding options are limited or undesirable.Q: What maintenance does the Rotary Cono Weeder require?

A: This tool has low maintenance needs. After use, wash off soil and debris, inspect for wear on the drums and moving parts, dry thoroughly to prevent rust, and store in the provided corrugated box.Q: How does the design enhance operator safety?

A: The weeder features covered moving parts, which significantly reduce the risk of injury during operation. Additionally, its lightweight build and manual operation enable easy and safe maneuvering, even over extended periods.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Email

Send Email

Send Inquiry

Send Inquiry Send SMS

Send SMS